CR-M5575 for PA66 (V0@0.4mm)

Inovia CR-M5575 is a new halogen-free flame retardant developed for PA66. Adding about 8% would reach UL94 V0 at 0.4mm. The flame retarding performance is quite stable, which is different from traditional MCA. And the impact strength property of the obtained PA66 is obviously improved, compared to similar products on the market.

1. Materials

PA66: Shenma EPR27

Retardant: Inovia CR-M5575

2. Processing

2.1 Drying: 100°C, 4~6 hours.

2.2 Extrusion temperature: 240/265/270/265/255/250/245/250/260/265°C

2.3 Injection temperature: 270~280°C; mold temperature: 80°C

Note: "PA66" in the diagram refers to PA66 pure resin after extruding.

3. Application Example Data

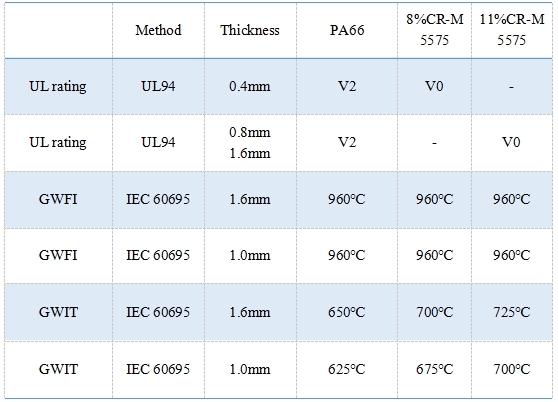

Table 1. Flame Retarding Properties

Table 2. Mechanical and thermal properties

Table 3. Other properties

Summary

CR-M5575 when used in PA66 can afford V0@0.4mm, which is quite stable. What’s more, the impact strength is much better than the benchmark products from some international plastic companies.

![]() PA66 Retardant CR-M5575_TDS.pdf

PA66 Retardant CR-M5575_TDS.pdf

![]() PA66 Retardant CR-M5575-SDS.pdf

PA66 Retardant CR-M5575-SDS.pdf