DR-M878 for Opaque PC Products

DR-M878 is a new high-efficiency flame retardant developed for PC polycarbonate, suitable for preparing PC thin-walled flame retardant products, including films, sheets, thin sheets, and thin-walled injection molded parts. DR-M878 does not contain halogens and does not require the addition of PTFE anti drip agents, which can perfectly meet the regulatory requirements of fluorine/halogen-free defluorination.

1. Materials

PC: Kesichuang PC 2805

Flame retardant: Inovia DR-M878

2. Processing

2.1 Drying: 120℃, 3 hours.

2.2 Use a high-speed mixer to mix DR-M878 with PC resin, and pay attention to controlling the internal temperature of the mixer to be less than 95 ℃.

2.3 Flame retardant PC particle extrusion temperature: 250~260 ℃

2.4 Recommended extrusion temperature for flame-retardant PC sheets: 260~275 ℃, recommended roller temperature: 80~110 ℃

2.5 Sheet thickness: 0.5 mm

3. Comparison of physical properties of flame-retardant PC sheets

Table 1. Flame retardant performance

Table 2. Mechanical Properties

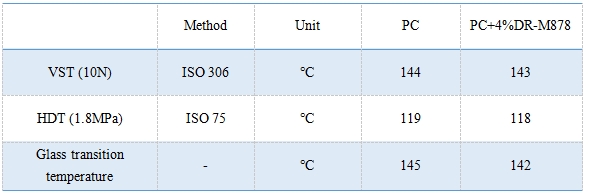

Table 3. Thermal Performance

Table 4. Flow Performance

Summary:

DR-M878 is a perfect flame retardant to make opaque PC film, sheet and thin-walled injection parts. It doesn’t contain halogen, nor require addition of PTFE. Compared to Inovia DR-S15, which is for transparent PC products, DR-M878 is much more economical, lower by more than 50%.