DR-S15 for Transparent PC Products

Inovia DR-S15 is a new flame retardant designed for polycarbonate plastic, especially for thin PC products (less than 2mm). It doesn't contain halogen, nor needs PTFE anti-dripping agent to reach UL V0. It is the first case in the world that can afford PC UL 94 V0 at a thickness from 0.1 to 1.6mm while the optical properties of PC remain intact.

1. Materials:

PC: Covestro Makrolon 2805

Flame retardant: Inovia DR-S15

2. Processing:

2.1 Drying: PC Resin is dried at 120°C for 3 hours in a vacuum oven. Inovia DR-S15 can be used as provided if its package is intact.

2.2 Extrusion temperature: 235~270°C

2.3 Injection temperature: 235~270°C, mold temperature: 80°C

Note: DR-S15 flame retardant or its masterbatch MB-PC10C (10%) can be supplied. Adding the flame retardant will increase the melting index significantly, therefore, the processing temperature will need to be lowered accordingly, by around 20~30℃. The plastic or masterbatch will need to be completely dried and the machine needs to be thoroughly cleaned, for ionic liquids has superior cleaning capacity.

3. PC Sheet Application Example Data

Table 1. Flame Retardancy

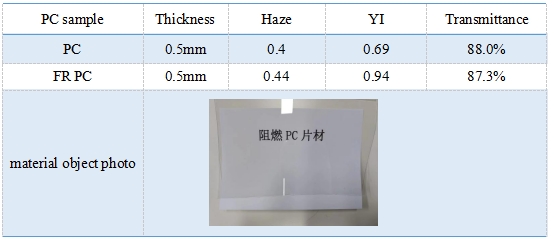

Table 2. Optical Properties

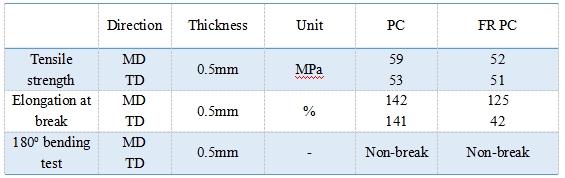

Table 3. Tensile and bending performances of flame-retardant PC sheet

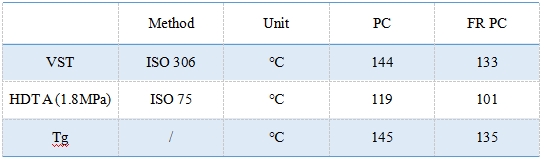

Table 4. Thermal Properties

![]() PC Retardant DR-S15-SDS US.pdf

PC Retardant DR-S15-SDS US.pdf